|

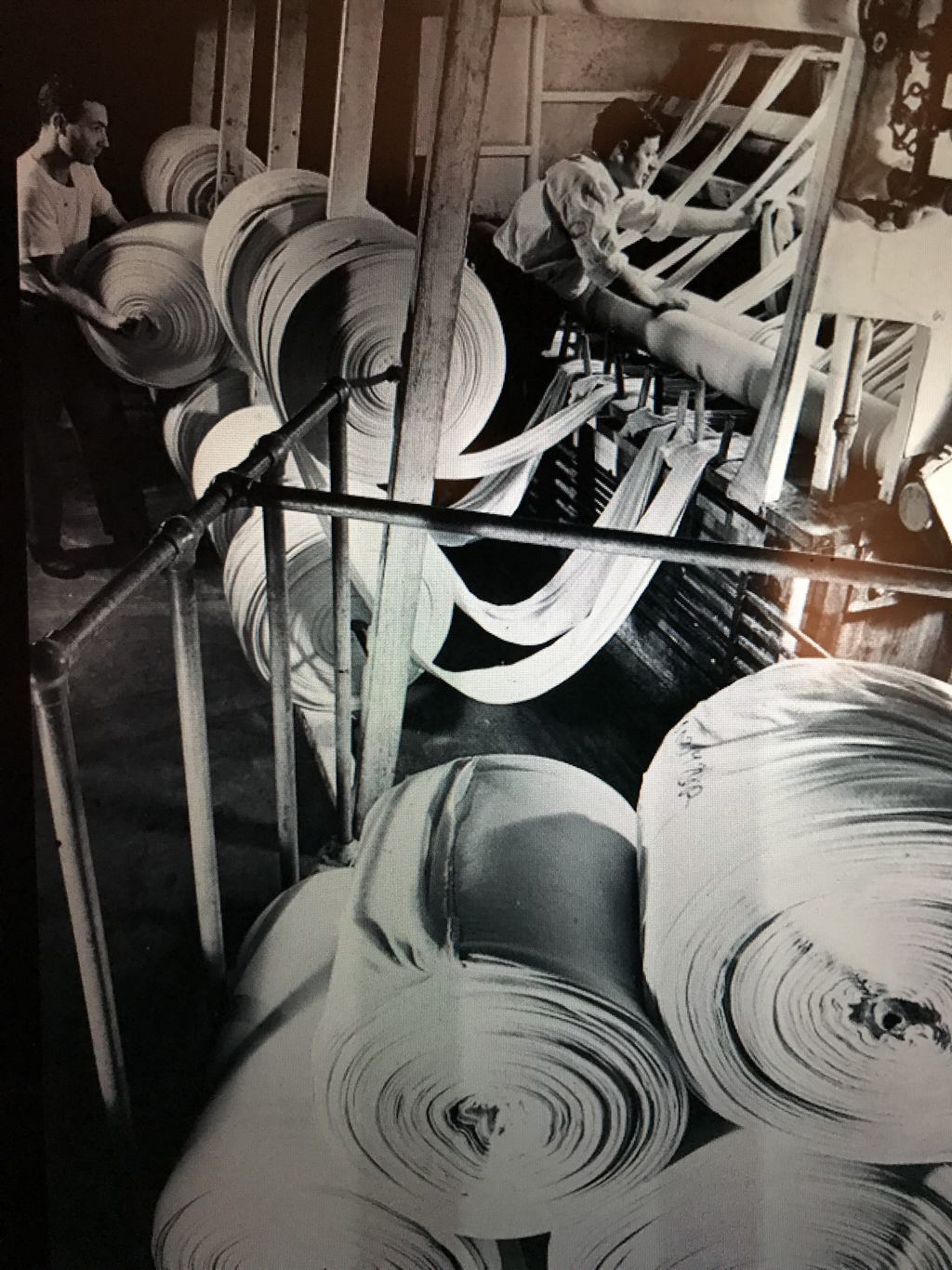

Above: men working in a dyehouse, 1940s Poem 38 Mill Work (a mock poem testimony) by Rich McCarthy, 2011 I was a Lawrence High School student in the 40s. The mills were humming: The Wood Mill, the Ayer Mill, the Arlington, the Pacific. Most every kid had a parent or relative working in a mill. My grandfather had been a weaver here Since he left Vermont at age nineteen (When his father died and the barn burned down.) [My note: the death of his father after a balloon accident is covered in another blog post.] In High School The worst the future could hold for us Was to end up in a mill after graduation We joked about becoming a mill rat. . . no way. My poor dad was a mill rat... in the dye house. And what did I do after I graduated. I took a job. Where? In a dye house. Like dad, I became a “jig” operator It wasn’t bad work; Except for the fumes: The hydrochloric acid, the ammonia, and the formaldrahyde fumes... Whew, sometimes it was overwhelming. I met some interesting people, Like the guy who never wore a shirt And had blue birds tattooed on his chest, One on each breast. Flying towards each other. I only lasted for two months. It wasn’t for me, a kid. I didn’t have to support a family. I left for a job with a magazine distributor. I was out of the mill. It was clean work: Putting up orders for drug stores. But the pay, 65 cents an hour, Stunk So what did I do? I went back to the mill. (The American Woolen Company) One buck an hour? I couldn’t believe it With benefits to boot! A Union shop, the CIO. So there I was, A back-boy Working the second shift, (two to ten), In the mule spinning room. The temperature was hot And humid. . . 90 degrees plus Humidifiers keeping it moist So the ends would not fall. The sweat poured over our brows We all wore head bands To keep it out of the eyes It was so hot we wore pants cut off at the knee, That’s all, no shirt, bare backed And old shoes with no socks It was a nice place to be in a winter storm, tropical. Cockroaches abounded. I stuck it out for about a year. The mills were shutting down, Moving south Where cheaper labor could be found, Or so we heard. So I got “laid off". .. permanently. Lawrence fell into hard times. The textile industry, as Lawrence knew it, Collapsed. But the experience taught me About organized labor, unions. I had got a decent wage. Because the job was so dirty, We were allowed a shower On company time at shift’s end. Because of the union, When we cleaned rollers, The machinery was disengaged. (Back-boys had been killed in prior years, Crushed to death when switches Were accidentally pulled.) Funny, as I think of it, I never heard of the strike of 1912 Not from my working stiff relatives, not in school. So I’m glad this is not the case today In Lawrence. And that we now celebrate The gutsy spontaneous reaction Of exploited immigrants Who made a better future for mill workers... All workers. And I might say, for me personally, A kid back in 1949. Below: The Wood Mill and the Ayer Mill at night, south bank of the Merrimack River, Lawrence, Mass., 1940s

|

|

RSS Feed

RSS Feed